Top Combiner Box Solutions: Leading Companies and Innovative Systems

2026-01-01

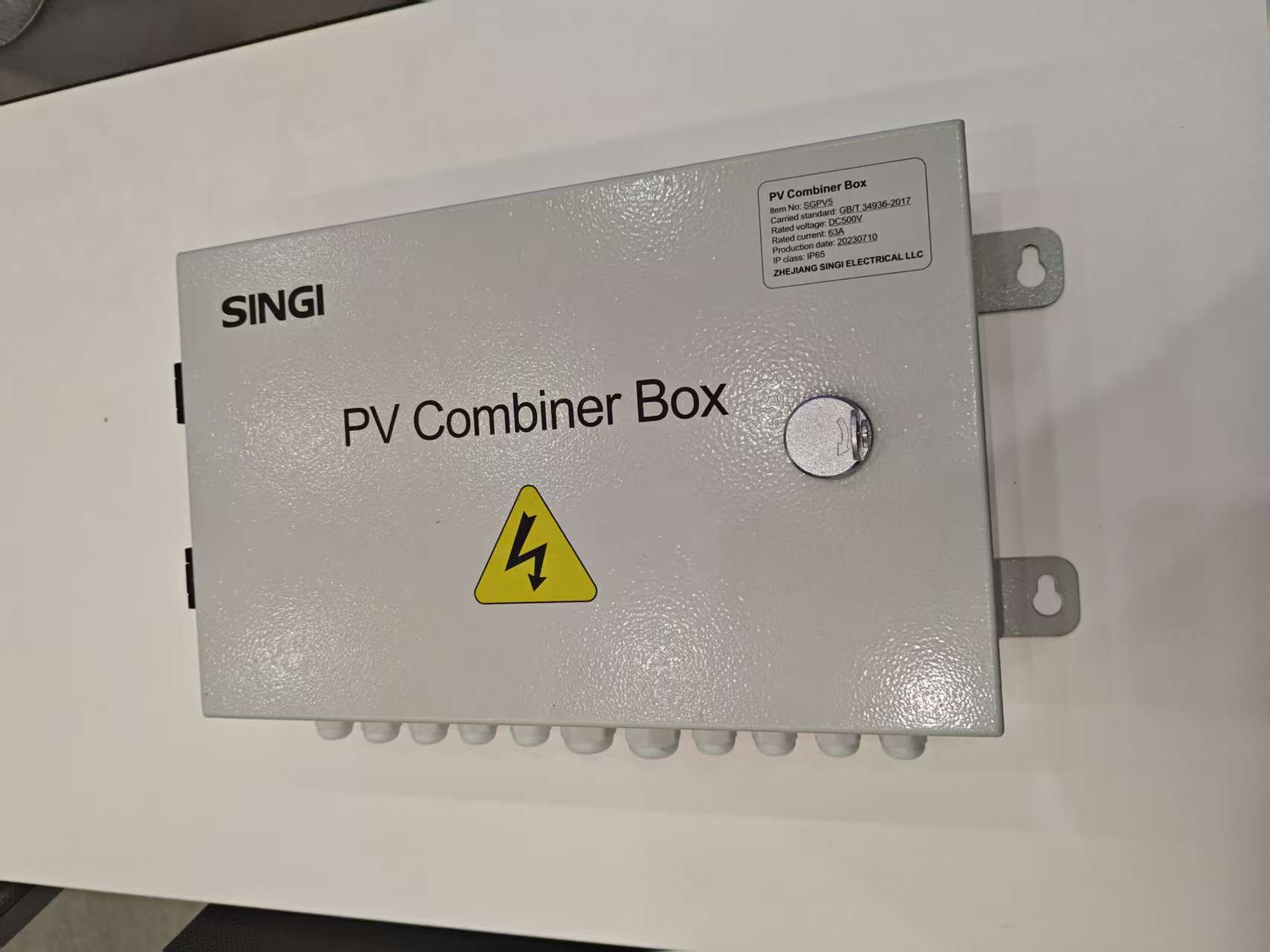

In the rapidly evolving world of solar energy, combiner boxes play a critical role in optimizing system performance and safety. As a key component, they ensure that multiple strings of solar panels are efficiently managed and protected. This blog, titled 'Top Combiner Box Solutions: Leading Companies and Innovative Systems', explores the forefront of this technology, highlighting innovative approaches and industry leaders shaping the future of renewable power. At SINGI, we're passionate about advancing solar solutions that drive sustainability and efficiency. In this post, you'll discover cutting-edge combiner box systems, learn about top companies pushing the envelope, and gain insights into how these innovations can benefit your projects. Whether you're a seasoned installer or new to the field, this overview aims to spark curiosity and set the stage for deeper dives into the dynamic landscape of solar energy solutions.

Top Manufacturers of Advanced Combiner Boxes for Solar Applications

The market for advanced combiner boxes in solar applications is dominated by a handful of key players who consistently push the boundaries of innovation and reliability. Leading the pack is Schneider Electric, which has carved out a strong reputation for its durable, weather-resistant designs that seamlessly integrate with grid-tied systems. Their combiner boxes often feature smart monitoring capabilities, allowing operators to track performance metrics in real-time, which is a game-changer for large-scale solar farms. Companies like Eaton and ABB are also prominent, with Eaton focusing on modular, expandable solutions that cater to both residential and commercial installations, while ABB emphasizes safety with advanced arc-fault detection and rapid shutdown mechanisms. These manufacturers don't just sell boxes; they provide comprehensive systems that enhance overall solar efficiency and longevity.

Beyond the giants, niche innovators are making waves by addressing specific pain points in the industry. For instance, SolarEdge has gained traction with its power optimizer-integrated combiner boxes, which maximize energy harvest from each panel even under shading or mismatched conditions—a common issue in rooftop setups. Meanwhile, companies like Chint and Enphase Energy focus on user-friendly designs, offering plug-and-play installations that reduce labor costs and downtime. These players often partner with installers to refine their products based on real-world feedback, ensuring they're not just technologically advanced but also practical on the ground. This blend of high-tech features and hands-on usability sets them apart in a crowded market.

The competitive landscape is further shaped by regional leaders that tailor their offerings to local climates and regulations. In North America, manufacturers like Advanced Energy and KACO new energy prioritize compliance with strict safety standards, such as NEC requirements, while also incorporating robust thermal management for harsh environments. In contrast, European brands like SMA Solar Technology emphasize grid stability features, supporting the continent's push toward renewable integration. As solar adoption grows globally, these manufacturers are increasingly focusing on sustainability too, using recyclable materials and energy-efficient production methods. Ultimately, choosing a top manufacturer isn't just about specs; it's about finding a partner that aligns with your project's unique demands, from durability to smart functionality.

Innovative Systems Enhancing Safety and Efficiency in PV Arrays

Implementing cutting-edge technologies in PV arrays has transformed how we manage energy production, focusing on both safety and performance. Smart monitoring systems now integrate real-time data analytics to detect anomalies like micro-cracks or shading issues, preventing potential hazards before they escalate. By leveraging IoT sensors and AI-driven algorithms, these innovations minimize downtime and ensure consistent power output, making solar installations more resilient in diverse environmental conditions.

Beyond monitoring, advanced protection mechanisms enhance safety by incorporating features such as rapid shutdown devices and arc-fault circuit interrupters. These systems automatically isolate faulty sections during emergencies, reducing fire risks and safeguarding both equipment and personnel. This proactive approach not only meets stringent safety standards but also boosts operational confidence, allowing for larger-scale deployments in residential and commercial settings without compromising reliability.

Efficiency gains are further amplified through optimization tools like maximum power point tracking (MPPT) controllers and dynamic reconfiguration capabilities. These systems adjust panel configurations on-the-fly to maximize energy harvest under varying sunlight and temperature conditions. By minimizing energy losses and improving overall yield, such innovations contribute to lower costs and enhanced sustainability, reinforcing PV arrays' role in modern energy grids as dependable and intelligent solutions.

Customizable Combiner Box Designs for Diverse Renewable Energy Projects

Customizable combiner boxes are essential in renewable energy projects because they adapt to the specific needs of different setups, such as solar, wind, or hybrid systems. By offering tailored configurations, these boxes simplify the integration process, reduce installation time, and enhance overall system efficiency, ensuring that each project operates at its peak performance regardless of scale or complexity.

The flexibility of these designs allows engineers to choose from various materials, sizes, and features, like weatherproof enclosures or modular components, which can be adjusted on-site. This adaptability not only meets diverse environmental conditions but also helps in future expansions or modifications, making it a cost-effective solution for evolving energy demands in a dynamic market.

Moreover, the focus on customization empowers project managers to optimize space and resources effectively, leading to lower maintenance costs and increased reliability. As renewable energy technologies advance, these combiner boxes serve as a cornerstone in building resilient, adaptable infrastructures that support sustainable development goals across different regions and applications.

Key Players Driving Technological Evolution in Power Distribution Units

The transformation of power distribution units (PDUs) into intelligent systems is championed by a diverse group of innovators. Leading hardware manufacturers like Schneider Electric and Eaton are pushing the envelope with modular, high-efficiency designs that integrate seamlessly into modern data centers. These companies aren't just selling boxes—they're crafting solutions that monitor energy use in real time, predict failures before they happen, and adapt to fluctuating power demands without breaking a sweat. It's this relentless focus on reliability and smart connectivity that keeps critical infrastructure humming smoothly.

Beyond traditional giants, agile software developers and IoT specialists are injecting fresh ideas into the PDU landscape. Start-ups and tech firms are creating intuitive platforms that turn raw power data into actionable insights, allowing facility managers to optimize energy consumption down to the rack level. Think of it as giving power distribution a brain—these players enable features like remote troubleshooting, automated load balancing, and granular reporting that old-school PDUs could only dream of. Their contributions make power management not just a necessity, but a strategic advantage in today's fast-paced digital world.

Regulatory bodies and industry alliances also play a crucial, often overlooked role in shaping PDU evolution. Organizations like the U.S. Department of Energy and the Green Grid consortium set standards and promote best practices that drive innovation toward sustainability and safety. By advocating for energy-efficient certifications and stricter compliance guidelines, they nudge the entire industry toward greener, more resilient power solutions. This collaborative push ensures that technological advances in PDUs aren't just about cutting-edge features, but also about meeting the growing demand for eco-friendly and secure power infrastructure.

Trendsetting Features in Modern Combiner Box Solutions for Grid Integration

Modern combiner boxes have evolved significantly from their basic origins, now incorporating advanced features that streamline grid integration processes. Many of today's solutions integrate smart monitoring capabilities, allowing operators to track performance metrics like current, voltage, and temperature in real-time. This not only enhances safety by detecting anomalies early but also optimizes energy output by identifying underperforming strings quickly. Some models even include remote control functions, enabling adjustments without physical access to the site, which is especially useful in large-scale solar or wind farms.

Another standout trend is the emphasis on modularity and scalability, with designs that can be easily expanded as renewable energy projects grow. Manufacturers are offering compact, weather-resistant enclosures that reduce installation time and maintenance costs, often using durable materials like stainless steel or high-grade polymers. These boxes also feature improved connectivity options, such as built-in communication protocols like Modbus or Ethernet, facilitating seamless data exchange with SCADA systems and other grid management tools. This integration helps utilities balance supply and demand more effectively, supporting the transition to a smarter, more resilient power grid.

Innovations in safety and reliability are also shaping modern combiner boxes, with features like arc-fault detection and rapid shutdown mechanisms becoming standard in many regions. These enhancements address key regulatory requirements and reduce fire risks in photovoltaic systems. Furthermore, some solutions incorporate predictive maintenance algorithms that analyze historical data to forecast potential failures, allowing for proactive servicing before issues escalate. By combining these elements, modern combiner boxes not only improve operational efficiency but also contribute to the overall stability and sustainability of grid-connected renewable energy systems.

User-Friendly Designs for Easy Installation and Maintenance in Solar Farms

When it comes to solar farms, making installation and maintenance straightforward is key to keeping projects on schedule and within budget. Rather than complex setups that require specialized tools or extensive training, we focus on intuitive layouts and modular components. This approach minimizes downtime during initial setup and allows for quick replacements or upgrades down the line, ensuring the system remains efficient without unnecessary hassle.

For instance, incorporating color-coded wiring and clearly labeled junction boxes can drastically reduce the time technicians spend troubleshooting. Additionally, designing panels that snap together easily or use simple fastening mechanisms eliminates the need for heavy machinery in many cases. These thoughtful touches not only speed up the process but also make routine checks more accessible, empowering field teams to perform tasks confidently and safely.

Maintenance is often the unsung hero of solar farm longevity, and user-friendly designs ensure it doesn't become a chore. By placing access points at ergonomic heights and using durable, weather-resistant materials that don't require frequent upkeep, we cut down on long-term costs. Ultimately, prioritizing ease in every detail means solar farms can operate smoothly, adapting to changes with minimal disruption and maximizing energy output from day one.

FAQ

Top combiner box solutions are characterized by high reliability, advanced safety features like arc fault detection, and integration capabilities with smart monitoring systems, enabling efficient energy management and reduced maintenance costs.

Companies such as Eaton, SMA Solar Technology, and FIMER are at the forefront, with Eaton focusing on robust enclosures for harsh environments, SMA on grid-tie solutions, and FIMER on modular designs for scalability.

They incorporate multiple protection layers, including overcurrent and surge protection, along with real-time monitoring to detect issues like ground faults or overheating before they lead to hazards.

Smart technology enables remote monitoring and control via IoT platforms, allowing users to track performance, optimize energy output, and receive alerts for proactive maintenance without on-site inspections.

Yes, leading systems offer flexible configurations; residential models are compact and easy to install, while utility-scale versions are designed for high-capacity connections and durability in large arrays.

By improving efficiency and reducing downtime through predictive maintenance, these solutions lower operational expenses and enhance return on investment over the system's lifetime.

They seamlessly connect inverters, batteries, and charge controllers, often featuring plug-and-play interfaces that simplify installation and ensure compatibility in hybrid energy setups.

Conclusion

In the competitive landscape of solar power systems, top manufacturers of advanced combiner boxes are setting new benchmarks by focusing on safety and efficiency. These key players drive technological evolution by integrating innovative systems that enhance performance in PV arrays, ensuring reliable power distribution and minimizing risks. Their solutions feature cutting-edge designs that protect against environmental hazards and electrical faults, making modern combiner boxes indispensable for sustainable energy projects. By prioritizing robust construction and smart monitoring capabilities, these companies deliver products that withstand harsh conditions while optimizing energy output from solar installations.

Moreover, customizable combiner box designs cater to diverse renewable energy projects, offering flexibility for varied applications from small-scale setups to large solar farms. Trendsetting features, such as modular components and grid integration tools, enable seamless adaptation to evolving infrastructure needs. User-friendly designs simplify installation and maintenance, reducing operational downtime and costs. This emphasis on accessibility and innovation not only supports the growth of solar farms but also positions these systems as pivotal elements in advancing global renewable energy goals, blending practicality with forward-thinking engineering to meet future challenges.

Contact Us

Contact Person: Jack

Email: [email protected]

Tel/WhatsApp: (+86) 13757759651

Website: https://www.singi.com