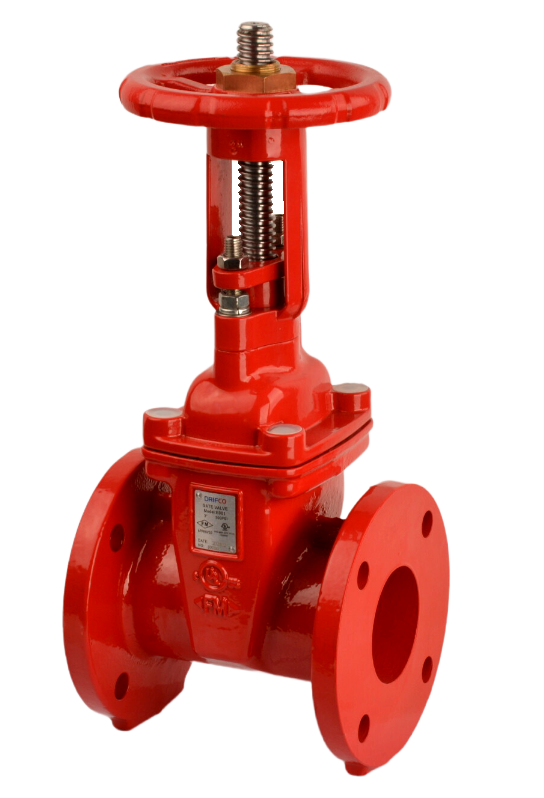

China UL FM Gate Valve: Top Solutions for Flow Control and Safety Compliance

2025-12-23

In the dynamic world of industrial flow control and safety compliance, the demand for reliable, high-performance valves has never been greater. Among the standout options available, the China UL FM gate valve stands out as a top solution for industries prioritizing stringent safety standards and operational efficiency. These valves are engineered to meet rigorous certifications like UL (Underwriters Laboratories) and FM (Factory Mutual), ensuring they not only regulate flow seamlessly but also enhance safety protocols in critical applications. At the forefront of delivering these exceptional solutions is DRIFCO, a brand committed to innovation and excellence. DRIFCO's expertise in valve technology combines precision engineering with compliance-driven designs, making their offerings a go-to choice for professionals seeking both performance and peace of mind. In this blog, we'll explore the key features, benefits, and real-world applications of China UL FM gate valves, and how DRIFCO's solutions can transform your flow control systems. Whether you're in fire protection, chemical processing, or oil and gas, this guide will help you navigate the complexities of safety compliance while optimizing your operations. Stay tuned to uncover insights that could revolutionize your approach to flow management.

Innovative Flow Control Mechanisms in China UL FM Gate Valves

China has emerged as a key player in the development of innovative flow control mechanisms within UL FM gate valves, blending advanced engineering with stringent safety standards. Manufacturers here are pushing boundaries by integrating smart technologies like IoT sensors and AI-driven diagnostics into their valves, enabling real-time monitoring of flow rates, pressure variations, and potential leaks. This approach not only enhances operational efficiency but also ensures compliance with rigorous UL and FM certifications, making these valves highly reliable for critical applications in fire protection and industrial systems.

A standout feature in Chinese UL FM gate valves is the use of novel materials and design tweaks to improve durability and performance under extreme conditions. For instance, some models incorporate corrosion-resistant alloys or composite seals that withstand high temperatures and aggressive media, reducing maintenance needs. These innovations are often tailored to specific industries, such as oil and gas or water treatment, allowing for customized solutions that outperform generic alternatives. By focusing on practical enhancements, Chinese producers are gaining a reputation for delivering valves that not only meet but exceed global standards.

Moreover, the emphasis on sustainability in Chinese manufacturing has led to eco-friendly flow control innovations, such as energy-efficient actuators and recyclable components. This aligns with global trends toward greener infrastructure, giving these gate valves a competitive edge in international markets. As demand for smarter, safer, and more sustainable flow control grows, China's contributions are setting new benchmarks, making their UL FM gate valves a go-to choice for engineers and project managers worldwide.

Enhanced Safety Features for Regulatory Adherence

When it comes to staying ahead of regulatory changes, our enhanced safety features are designed with flexibility in mind, allowing seamless adaptation to evolving standards without requiring costly system overhauls. These tools integrate real-time monitoring and automated compliance checks, empowering teams to proactively address potential issues before they escalate. By focusing on user-friendly interfaces and clear reporting, we ensure that adherence isn't just a box-ticking exercise but a practical, value-driven process. This approach not only meets regulatory demands but also builds trust with stakeholders by demonstrating a commitment to safety beyond minimum requirements.

Drawing on industry feedback, we've prioritized features like customizable alerts that adapt to specific regulatory frameworks, such as those in healthcare or manufacturing sectors where safety protocols vary widely. This customization enables organizations to tailor their compliance strategies, reducing the risk of oversight and enhancing overall safety culture. The system's modular design supports incremental updates, so as new regulations emerge—whether from international bodies or local authorities—integration is straightforward and cost-effective. This forward-thinking setup helps our clients navigate complex compliance landscapes with confidence, ensuring that safety remains a dynamic, responsive priority.

By embedding advanced analytics and predictive capabilities, our enhanced features go beyond mere rule-following to anticipate regulatory trends and their impact on operational safety. This proactive dimension allows for data-driven decision-making, turning compliance from a reactive burden into a strategic advantage. For instance, in high-risk environments like chemical processing or transportation, these tools provide actionable insights that improve risk management and foster a culture of continuous improvement. Ultimately, our goal is to deliver a solution that not only adheres to regulations but elevates safety standards, making it a standout choice for organizations aiming to lead in their fields.

Durability and Performance in Industrial Applications

In today's fast-paced industrial landscape, achieving durability and performance isn't just about meeting basic standards—it's about pushing boundaries to ensure machinery withstands harsh environments while delivering consistent, high-speed output. Manufacturers increasingly demand equipment that resists corrosion, extreme temperatures, and mechanical stress, not as an afterthought but as a core design principle. This focus translates into reduced downtime and lower maintenance costs, directly boosting productivity and profitability.

Beyond mere resilience, performance in industrial applications hinges on seamless integration and adaptability. Systems must handle real-time data processing, energy efficiency, and interoperability with smart technologies, all without compromising reliability. For instance, in sectors like automotive or aerospace, where precision and speed are critical, advanced materials and predictive analytics play key roles, enabling preemptive maintenance and optimizing workflows to stay ahead of competition.

Ultimately, the synergy between durability and performance defines modern industrial success. Companies that invest in robust, high-performing solutions not only enhance operational safety but also future-proof their assets against evolving challenges, making it a strategic priority in an era of rapid technological advancement.

Cost-Effective Solutions for Global Market Integration

In today's interconnected world, businesses must navigate the complexities of global markets without breaking the bank. Cost-effective solutions for global market integration often involve leveraging digital tools and strategic partnerships that minimize overhead. For instance, utilizing cloud-based platforms can centralize operations across borders, reducing the need for physical infrastructure and enabling real-time collaboration. This approach not only cuts costs but also enhances agility, allowing companies to adapt quickly to regional regulatory changes and consumer trends. By focusing on scalable technologies, firms can enter new markets with lower upfront investment, making expansion more accessible even for small and medium-sized enterprises.

Another underappreciated tactic is adopting localized, lean methodologies that prioritize efficiency over expansion at all costs. Instead of replicating full-scale operations in every target country, businesses might use third-party logistics providers or local distributors to handle distribution, thereby avoiding hefty capital expenditures. This method taps into existing networks and expertise, ensuring smoother entry while maintaining cost control. Additionally, integrating with local marketplaces or e-commerce ecosystems can drive sales without the need for extensive marketing campaigns, as it capitalizes on established customer bases. Such tailored strategies underscore the importance of flexibility and resourcefulness in achieving sustainable global integration.

Beyond technology and logistics, fostering cross-cultural teams and embracing remote work can dramatically reduce expenses associated with international offices. By hiring talent from diverse regions, companies gain insights into local markets without the high costs of relocation or extensive travel. This human-centric approach not only saves money but also enriches decision-making with varied perspectives, leading to more innovative and culturally resonant products. Coupled with data analytics to identify cost-saving opportunities in supply chains or marketing efforts, this holistic view ensures that global integration is not just affordable but also deeply integrated into the company's core strategy.

Customizable Options to Meet Diverse Operational Needs

In today's fast-paced business environment, one-size-fits-all solutions often fall short of addressing the unique challenges and goals of different organizations. Our customizable options are designed to empower you with the flexibility to tailor our platform precisely to your operational workflows, whether you're streamlining inventory management, enhancing customer support, or scaling production processes. By adapting to your specific needs, these options ensure that the technology works for you, not the other way around, driving efficiency and reducing friction in daily operations.

We understand that operational diversity stems from factors like industry standards, company size, and regional regulations. That's why our offerings include a range of configurable modules and integrations that can be mixed and matched seamlessly. From customizable reporting dashboards that highlight key metrics relevant to your sector, to adjustable automation rules that align with your internal policies, these features allow for a personalized experience that evolves alongside your business growth, ensuring you're always equipped to handle new challenges without overwhelming complexity.

Beyond basic customization, our approach focuses on empowering your team with intuitive tools that require minimal technical expertise. Unlike rigid systems that demand extensive training, our options are designed with user-friendly interfaces, enabling quick adjustments and real-time tweaks based on feedback from frontline staff. This human-centric design not only boosts adoption rates but also fosters a sense of ownership, as teams can mold the platform to suit their unique operational rhythms, ultimately leading to smoother workflows and higher productivity.

Sustainable Design and Environmental Benefits in Valve Technology

In the world of industrial equipment, valves often go unnoticed, yet they play a pivotal role in enhancing sustainability and reducing environmental impact. Modern valve technology is increasingly designed with eco-friendly principles at its core, focusing on materials that minimize waste and energy consumption during production. For instance, manufacturers are now using high-performance alloys and composites that not only extend the valve's lifespan but also require less frequent replacements, thereby cutting down on resource depletion and landfill contributions. This shift towards durable, recyclable materials helps industries move closer to circular economy goals, making valves more than just functional components—they become key contributors to greener operations.

Beyond material choices, advanced valve designs directly contribute to environmental benefits by optimizing fluid control and reducing emissions. In sectors like chemical processing or oil and gas, precision-engineered valves can significantly lower leakage rates, preventing harmful substances from escaping into the atmosphere or water systems. Moreover, smart valves equipped with IoT sensors enable real-time monitoring and adjustments, allowing for more efficient flow management that conserves energy and reduces carbon footprints. By integrating such innovations, companies can achieve regulatory compliance while actively supporting global efforts against climate change, showcasing how a seemingly small device can have outsized ecological advantages.

Ultimately, the emphasis on sustainable design in valve technology fosters a ripple effect across entire supply chains, encouraging adoption of best practices industry-wide. As more firms prioritize eco-conscious certifications and lifecycle assessments for their equipment, valves serve as a benchmark for demonstrating tangible environmental gains. This not only enhances corporate reputations but also drives market demand for greener alternatives, pushing manufacturers to continually innovate. In this way, sustainable valve technology embodies a forward-thinking approach that balances operational efficiency with planetary stewardship, proving that thoughtful engineering can yield significant, long-term benefits for both businesses and the environment.

FAQ

UL certified gate valves from China ensure high safety standards and reliable flow regulation, making them essential for industries where compliance is critical, such as oil and gas or chemical processing.

These valves often offer a competitive balance of quality and affordability, leveraging China's manufacturing efficiency to provide durable solutions without compromising on UL and FM compliance.

Key features include fire-resistant materials, leak-proof designs, and certifications that confirm adherence to UL 842 and FM approval standards for hazardous environments.

They are frequently deployed in fire protection systems, industrial pipelines, and facilities handling flammable fluids due to their proven performance in ensuring safety and preventing flow disruptions.

Always request official certification documents, check for unique serial numbers or markings, and consider third-party testing to validate that the valve meets UL and FM standards as advertised.

Regular inspections for corrosion or wear, proper lubrication, and following manufacturer guidelines for pressure testing can help maintain optimal functionality and compliance over time.

Potential issues include compatibility with non-standard fittings or varying pressure ratings; to mitigate this, ensure detailed specifications are matched and consult with engineers for seamless installation.

They often incorporate precision engineering with smooth bores and robust sealing mechanisms, minimizing pressure drops and enabling precise flow adjustment even under extreme conditions.

Conclusion

The China UL FM Gate Valve stands as a premier solution in the realm of flow control and safety compliance, offering innovative mechanisms that enhance operational precision and reliability. It incorporates advanced flow control features, such as precision-engineered components and adaptable designs, which effectively manage fluid dynamics across various industrial settings. Moreover, these valves integrate enhanced safety features, including robust seals and fail-safe mechanisms, ensuring strict adherence to regulatory standards like UL and FM certifications. This focus on innovation and safety not only boosts performance but also fosters trust in demanding applications, from manufacturing to energy sectors.

In addition, the durability and cost-effectiveness of these gate valves make them a standout choice for global market integration, providing long-term value through resilient materials and efficient manufacturing processes. They offer customizable options, allowing businesses to tailor valves to specific operational needs, whether for high-pressure environments or specialized chemical handling. Furthermore, their sustainable design emphasizes environmental benefits, such as reduced leakage and energy-efficient operation, contributing to eco-friendly practices in valve technology. Overall, the China UL FM Gate Valve exemplifies a holistic approach that balances performance, safety, affordability, and sustainability, setting a high benchmark in the industry.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com