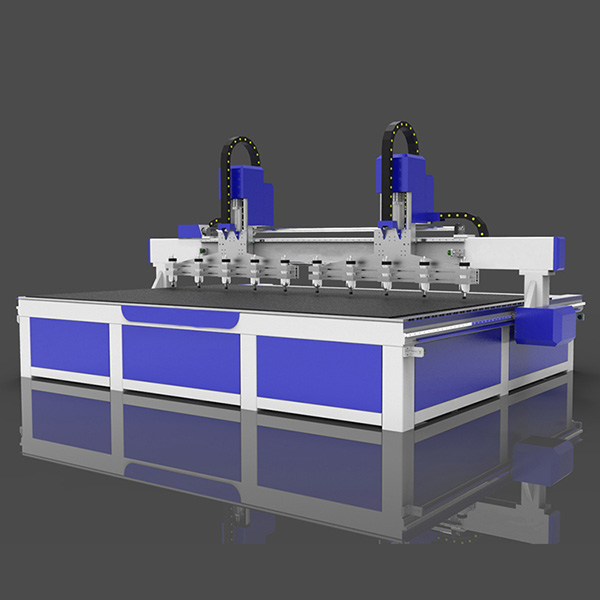

The Brief Introduction to Steel Forging

Steel forging is a manufacturing process that involves the shaping of metal using compressive forces. In this process, a steel billet is heated to a high temperature and then placed in a die or mold, where it is subjected to a series of hammer blows or pressurized impacts until it takes on the desir......

Send Inquiry

Product Description

Steel forging is a manufacturing process that involves the shaping of metal using compressive forces. In this process, a steel billet is heated to a high temperature and then placed in a die or mold, where it is subjected to a series of hammer blows or pressurized impacts until it takes on the desired shape. Steel forging can be used to produce a wide range of products, from small components to large industrial parts such as crankshafts, gears, and turbine blades. This process is preferred for its ability to produce strong, durable and reliable parts. There are following advantages:

1. Strength and durability: Steel forging produces parts that are stronger and more durable than parts produced by other manufacturing processes. The process involves compressive forces that help to align the grain structure of the metal, resulting in parts that are less likely to fail under stress or deformation.

2. Material properties: Forging can help to refine the grain structure of the steel, which in turn can improve its material properties such as toughness, impact resistance, and fatigue resistance.

3. Cost-effectiveness: While forging can be more expensive than other manufacturing processes like casting or machining, it can be more cost-effective in the long run because of the high strength and durability of the parts produced. This can result in a longer service life, fewer replacements, and reduced maintenance costs.

4. Customization: Forging can be used to produce parts of various sizes and shapes, allowing for a high degree of customization. This makes it a preferred process for producing parts that require specific dimensions or geometries.

5. Efficiency: The forging process is a highly efficient one that can produce parts quickly and with minimal waste. The process can also be automated, making it ideal for high-volume production.